FD25 AND FD50

› A drop-in replacement for most plastic modular belting

› Efficiently distributes torque across entire belt width

› Small minimum pulley diameter (50mm) for the 25mm pitch belt

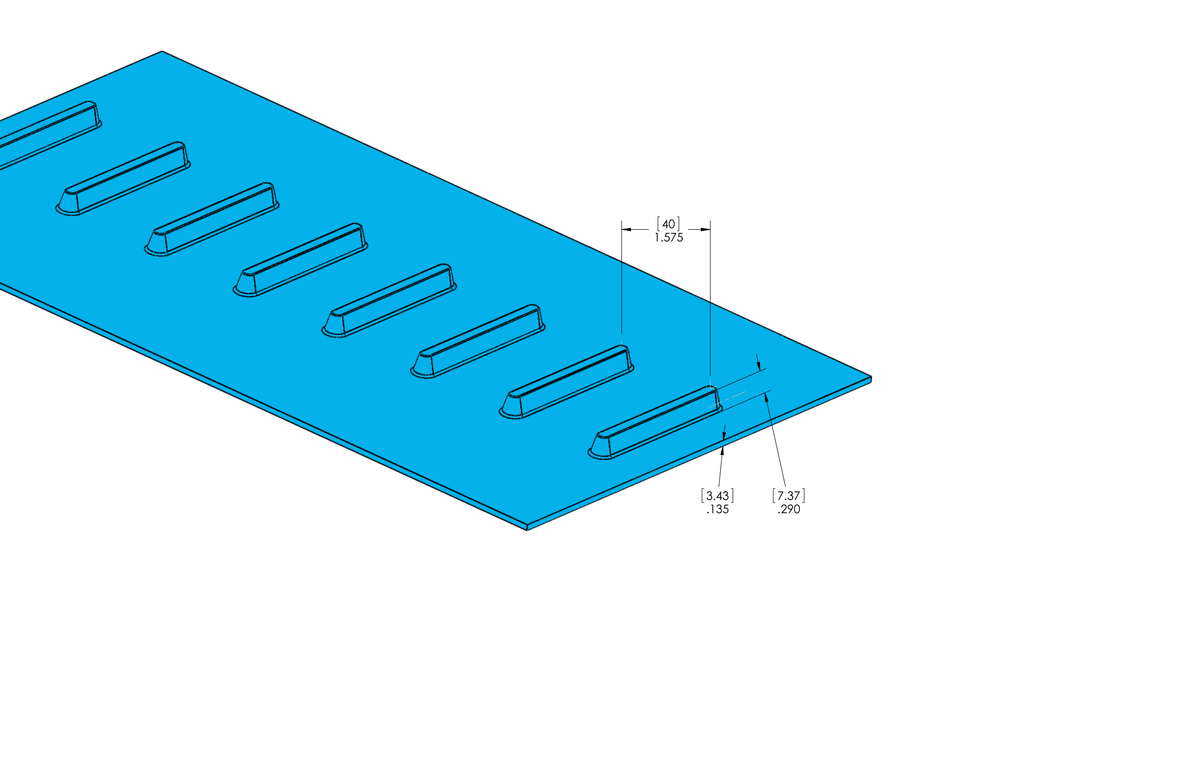

FD25

FD50

FB3 – corded only

› For frictional drive applications

› No frayed edges as often found on fabric-coated flat belting

› 50mm minimum pulley diameter for better handoffs

Available Surface Finishes

- Matte (standard)

- Gloss

- Inverted pyramid (TS)

- Diamond pattern with oval bottom (OT)

- Crescent top (CT)

- Sawtooth (ST)

Additives

Custom colors

Metal detectable

Governing Body Compliance

› Meets appropriate EC regulations and directives

› Meets USDA requirements for meat, poultry, and dairy equipment

› Meets FDA material requirements for wet food contact